- Volkan

- January 22, 2021

Loading / Unloading Containers & Trailers – Things To Consider

Many businesses involved in the importation and movement of loose goods face the challenge of handling loose products within containers and trailers. One crucial part that many companies overlook is the issue of how to unload the container or trailer at their premises. Consideration needs to be given to the many factors involved such as time and space constraints, manual labour requirements and loading dock availability.

Coveya offer a variety of solutions for loose loading/unloading and this article explores the popular methods that are available:

High-Rise Telescopic Unloading Conveyor:

Telescopic Gravity Roller. This is a gravity fed conveyor designed solely for unloading shipping containers and trailers without the use of a level loading dock. The conveyor can be wheeled up to a vehicle where it will extend up to 10.0m/32 foot and outside to an offload point at waist/ground height. The conveyor is very robust and is suitable for outdoor use. It is designed for handling boxes and cartons but can handle a much wider variety of materials.

Low-Level Telescopic Unloading & Loading Conveyor:

This is a gravity fed conveyor that has been designed for efficient loading / unloading of shipping containers and trailers with the use of a level loading dock. The conveyor has 4extending decks and has a fully extended length of 15m long. It has a robust build with a load capacity of up to 20kg per roller. It is designed for handling boxes and cartons but can handle a much wider variety of materials.

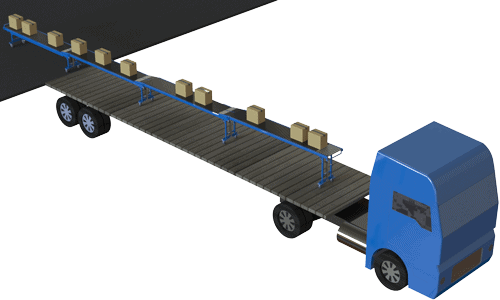

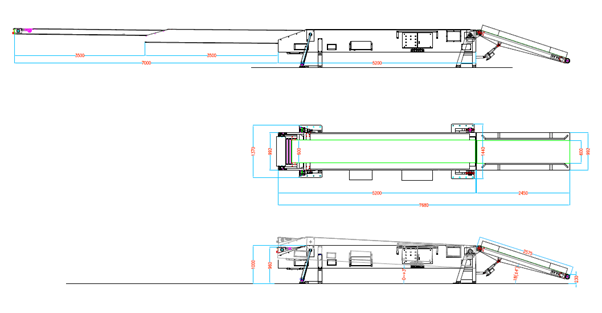

Telescopic Boom Conveyor:

The Telescopic Boom conveyor is an electric powered telescopic conveyor with a 6m base and a 12m extendable penetration length for use with a loading bay. It is available in a variety of different configurations and can be fitted with a mobile wheeled undercarriage, hydraulic discharge height adjustment or an additional off-load conveyor. These conveyors are manufactured for long term use and can offer payback times within 13 weeks!

Expandaveyor Conveyor:

Flexible Expanding Roller Conveyor. Available in a wide variety of lengths and widths this is one of the most versatile unit handling conveyors available. With adjustable discharge heights of 670mm –1100mm it can be set on a decline, loaded manually, and moved around with ease for use inside trailers & containers or to link up with existing machinery. Once you have finished using the conveyor you can simply close the unit up and store away.

Typically, companies who start using a conveyor for loose unloading and loading over their usual manual methods can see a reduction in unload times of 50%. The total man hours required to load/unload are also reduced by a similar amount.

You can get in touch with Coveya to explore what system is best and most suitable for you. We can provide a site assessment visit, a material trial and of course a quotation.

Coveya is the number one designer, manufacturer, and supplier of belt, gravity, mobile, radial, screw conveyors in the UK. Call us to speak with one of our experts for all your conveyor needs on 0117 956 3131

Distribution, demolition, recycle, waste management, water treatment, construction, reservoir maintenance…

We have a conveyor for you.